Environment

Environmental Policy

Recognizing that environmental issues are the most critical issue common to all humankind, our group operates by the following policy in all of our corporate activities to contribute to realizing a society where environmental conservation and economic development are in harmony.

- 1.We strive to preserve and improve the environment by focusing on energy-saving, resource-saving, and recycling.

- 2.We comply with applicable laws, regulations, and other requirements.

- 3.We strive to prevent accidents, disasters, and environmental pollution.

- 4.We strive to improve our environmental management system continuously.

Response to Climate Change

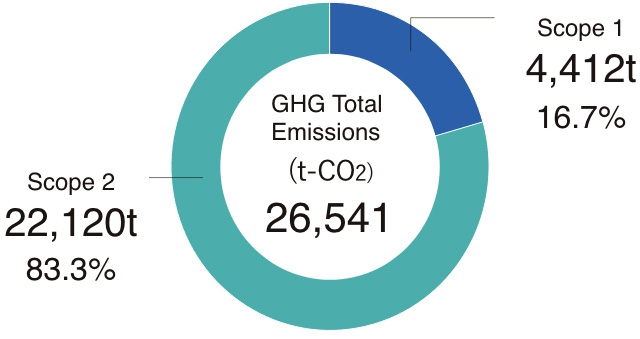

Greenhouse Gas(GHG) Emissions Reduction

The main energy sources used in our group’s business activities are electricity required for industrial gas production, which is our core business, and fuel for vehicles used in sales and delivery services. Electricity consumption accounts for 83.3% of our total greenhouse gas emissions. In particular, electricity consumption at the Tagajo Plant accounts for 78.8% of total greenhouse gas emissions, and we are working to reduce electricity consumption rates through measures such as adopting energy-saving equipment and improving the efficiency of production processes.Since FY2022, we have aligned the organizational scope of our energy usage data collection with the Ministry of the Environment’s guidelines1, and have been calculating our Group’s greenhouse gas emissions (Scope 1 and 2).To systematically reduce our greenhouse gas emissions going forward, we will adopt more energy-saving equipment at our production plants, switch to LED lighting in our offices, and promote the use of hybrid and electric vehicles for sales and security services, among other measures aimed at reducing supply chain emissions.

1. Basic Guideline for Calculating Greenhouse Gas Emissions through the Supply Chain (ver. 2.5).

-

FY2023 GHG Emissions from Main Energy Sources2

2.

2.- Scope 1:Direct emissions from fuel usage and production processes within the company.

- Scope 2:Indirect emissions from the use of electricity and other energy purchased by the company.

- The CO2 emissions for Scope 1 and 2 are calculated using the values from the Ministry of the Environment’s “Calculation Methods and Emission Factors List under the GHG Emissions Accounting, Reporting, and Disclosure System.”

-

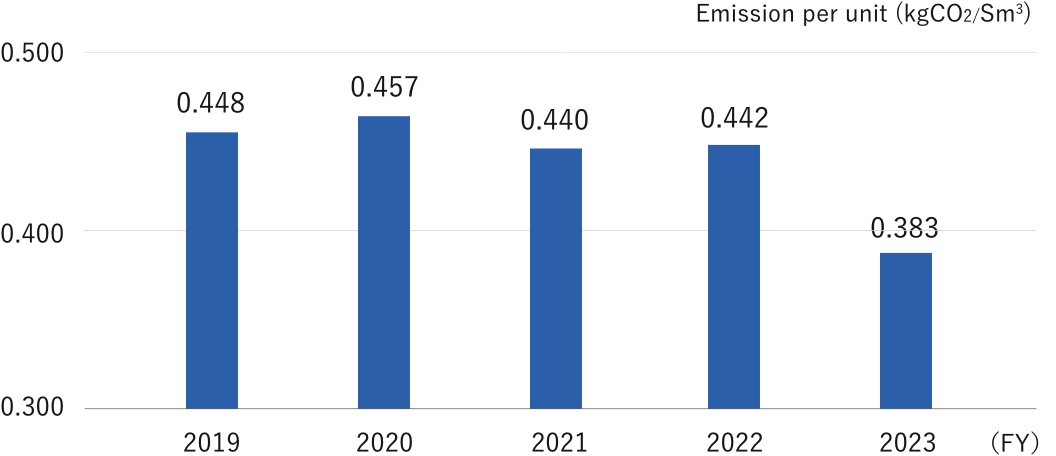

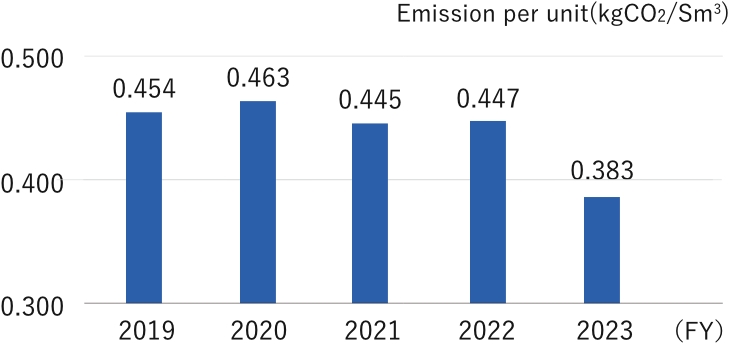

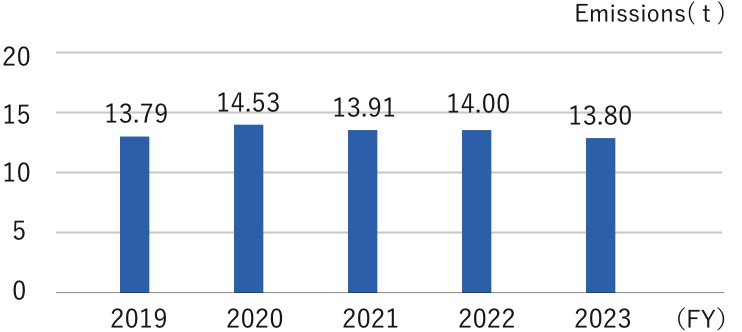

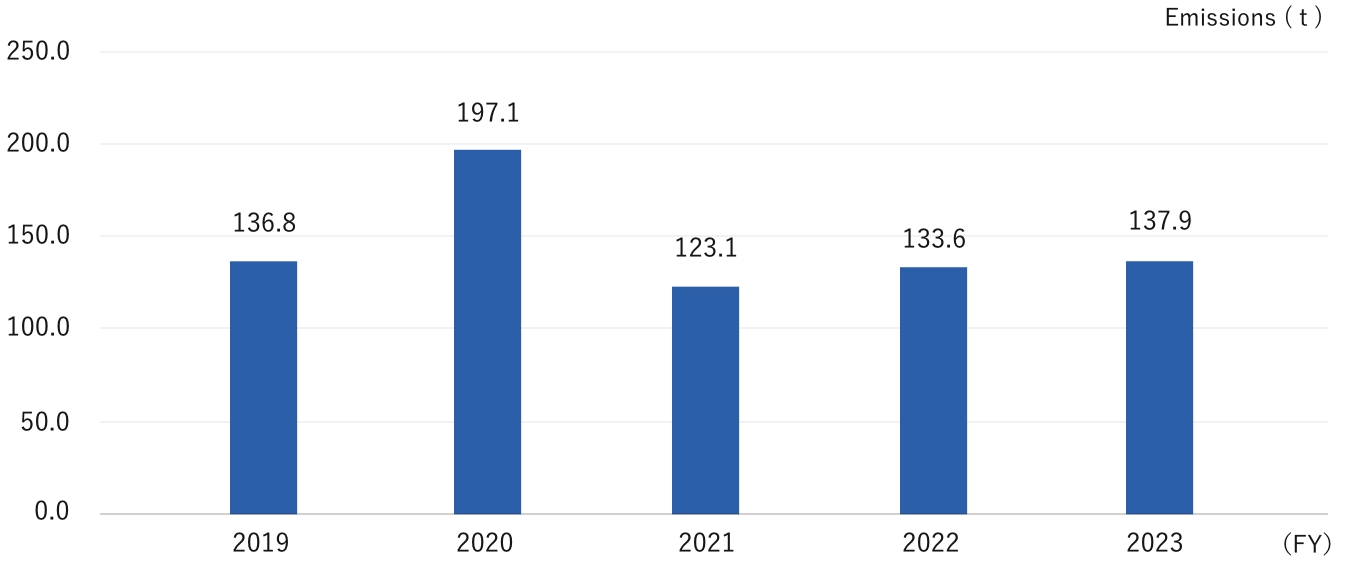

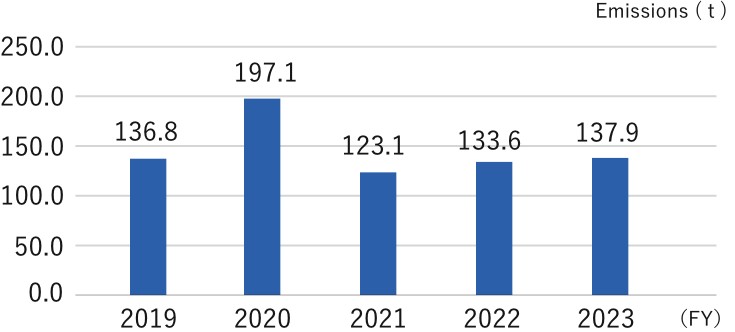

Carbon Dioxide Emissions per unit of Production

at Tagajo Plant

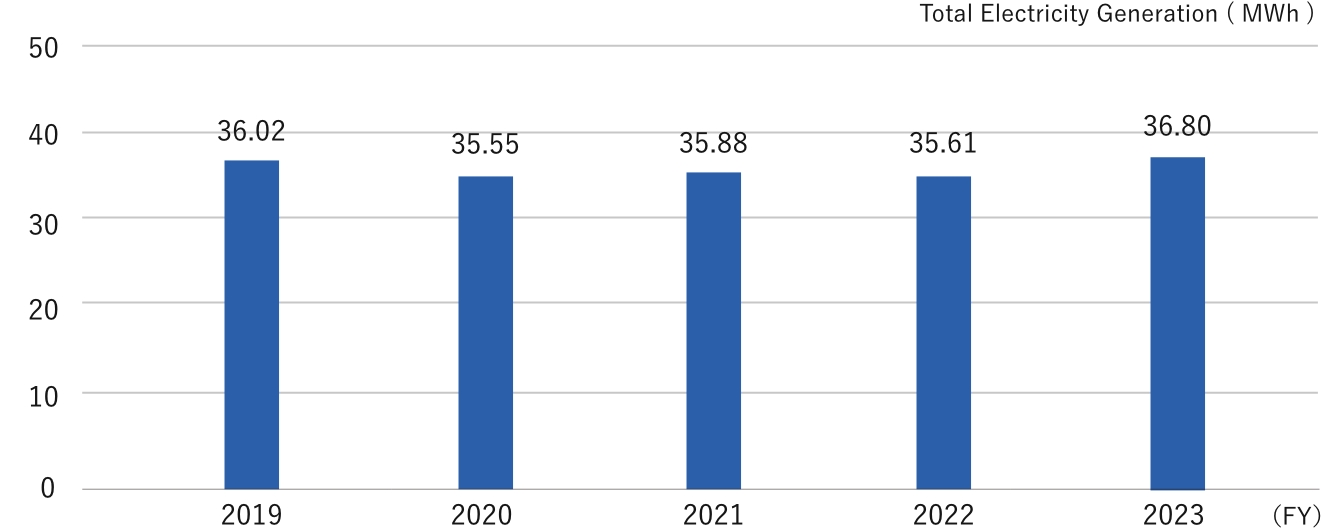

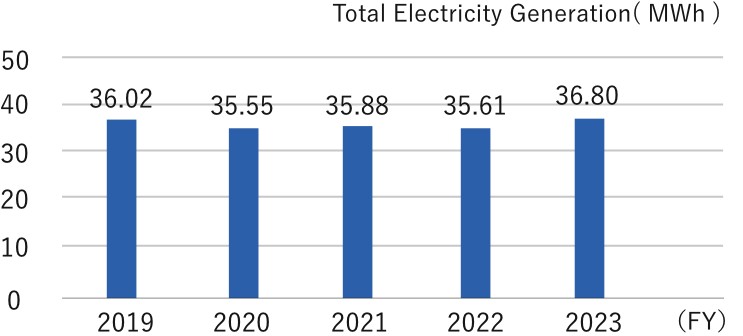

Renewable Energy Generation

Our group actively installs solar power generation equipment, supplying some electricity from photovoltaic panels to reduce electricity purchases.

-

Electricity Generation from Renewable Energy Sources

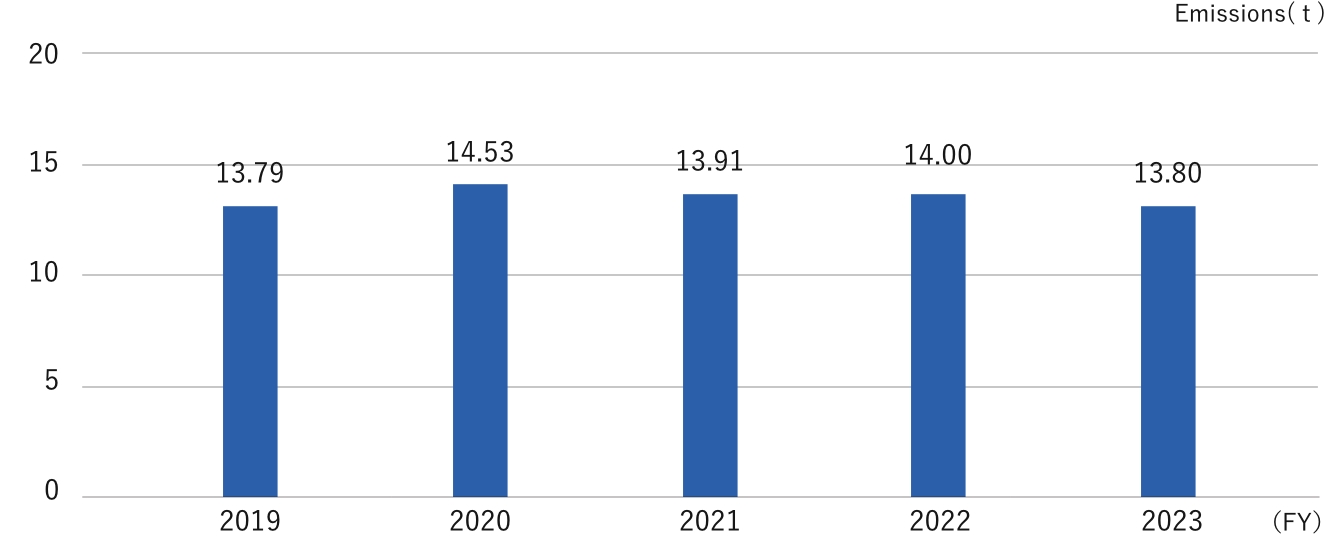

Emissions of Environmentally Hazardous Substances

We strive to manage and reduce emissions of substances emitted during the painting process of high-pressure gas containers subject to the PRTR law1 and VOCs2 targeted by the Air Pollution Control Law, as well as a freon (HCFC-223) used in the refrigeration equipment at the Tagajo Plant that is subject to the Ozone Layer Protection Law.

1. PRTR Law: Act on the Assessment of Releases of Specified Chemical Substances in the Environment and the Promotion of Management Improvement.

2. VOC: Volatile Organic Compounds.

3. HCFC-22: Amount replenished during refrigeration equipment maintenance.

-

Chemical Substance Emissions

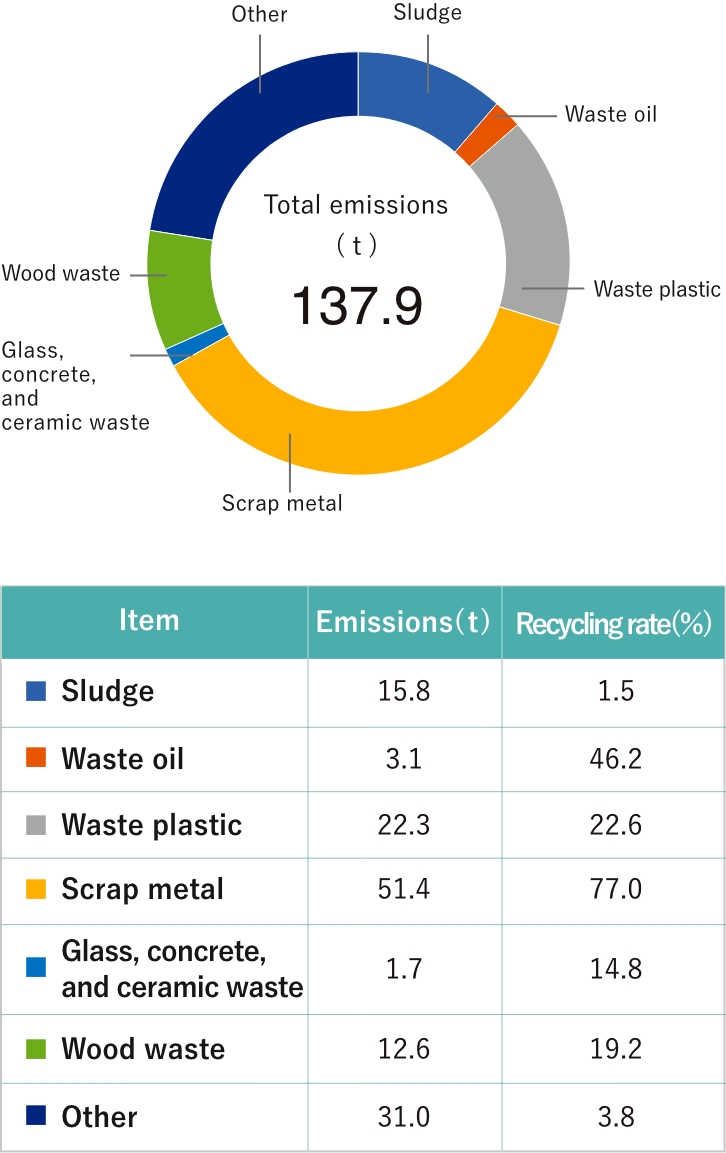

Efforts to Reduce Industrial Waste

Our group promotes the reuse of waste generated from business activities and strives to reduce waste generation by purchasing and using long-life products. We also manage the total amount of industrial waste generated across the group, survey the recycling rate of each disposal contractor, and work on promoting recycling activities.

-

FY2023 Industrial Waste Emissions and Recycling Rate

-

Industrial Waste Emissions

Environment & Quality Management System

Our group produces and supplies customers with industrial and medical gases such as oxygen, nitrogen, argon, hydrogen, and acetylene, called separate gases. In our gas production and supply activities, we recognize that ensuring quality and stable supply is our mission, and we strive to provide quality assurance by strengthening our analytical technologies and shipment control systems and conducting regular quality assurance audits at each of our plants.

Furthermore, to improve environmental performance and customer satisfaction, we have obtained the ISO 14001 certification for environmental management systems and the ISO 9001 certification for quality management systems at the Tagajo Plant and Toho Sakata Suiso Co., Ltd., a group company.

-

Standards

Standards Target Organization Registration Scope ISO 14001 Tagajo Plant Liquefied Gas Manufacturing

Division (Affiliated organization: Toho Sakata

Suiso Co., Ltd.)Manufacture of liquefied oxygen, nitrogen, argon,

and hydrogen gas

Registered on January 21, 2005ISO 9001 Tagajo Plant Liquefied Gas Manufacturing Division Manufacture of liquefied oxygen, nitrogen, and argon Toho Sakata Suiso Co., Ltd. Manufacture of hydrogen gas Registered on January 16, 2002 -

Acquisition of ISO Certification